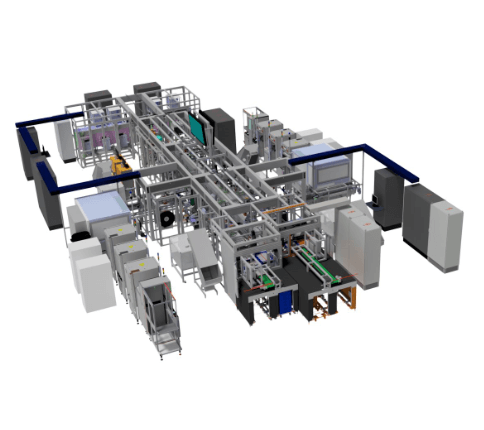

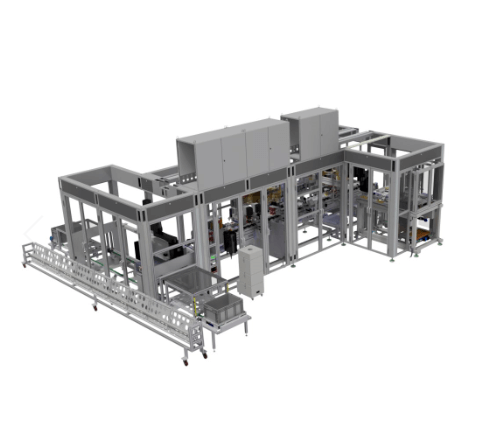

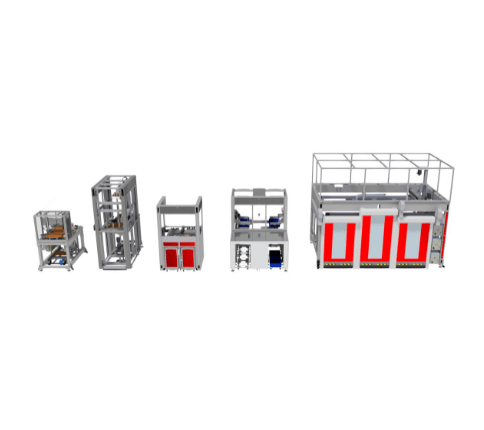

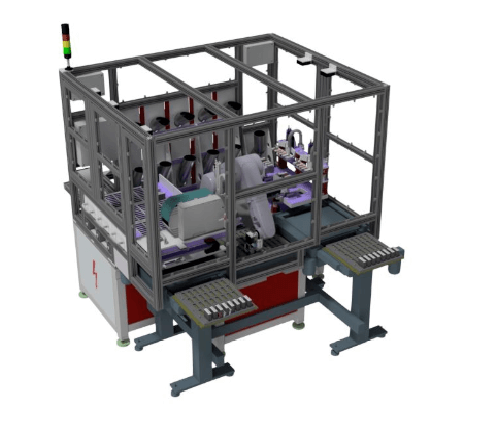

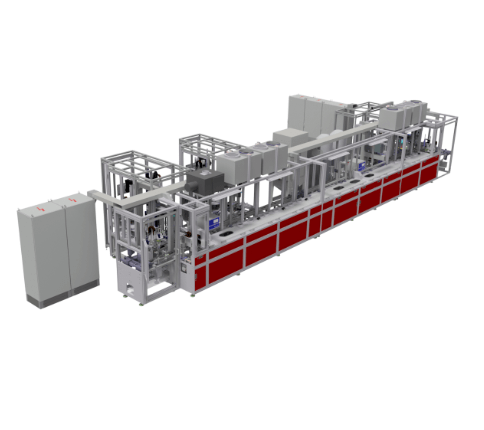

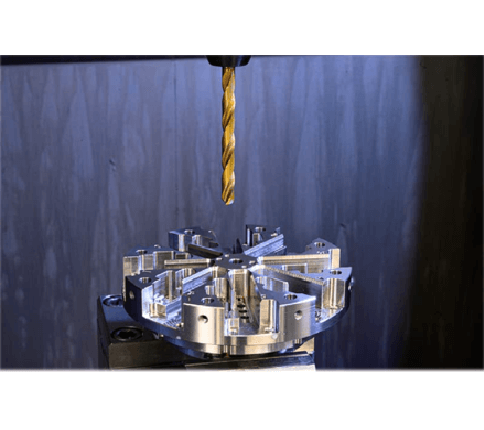

Automation, Industry 4.0 and Big Data are the biggest technology trends of our time. We at Braun recognised these trends early on and have used them consistently to develop highly automated special machines. With customised special machines we help you increase the productivity of your production lines and realise savings potential. We conceptualise, design and construct special machines, production plants, production lines and coating systems according to your individual ideas.

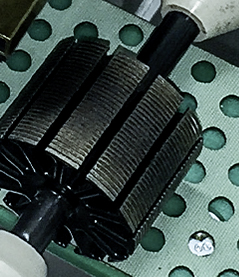

We have been there for you for over 40 years with our special machine construction services: Braun conceptualises, designs and constructs individual production plants and coating systems according to customers’ wishes. To do this, we draw on industry-wide technology trends such as electromobility, automation and Industry 4.0.

Are you looking for an experienced special machine construction company to optimise your production plants? Then you have come to the right place. With Braun Sondermaschinen GmbH you have an experienced automation partner at your side.