Powder coating I-pin and continuous Hairpin

Description

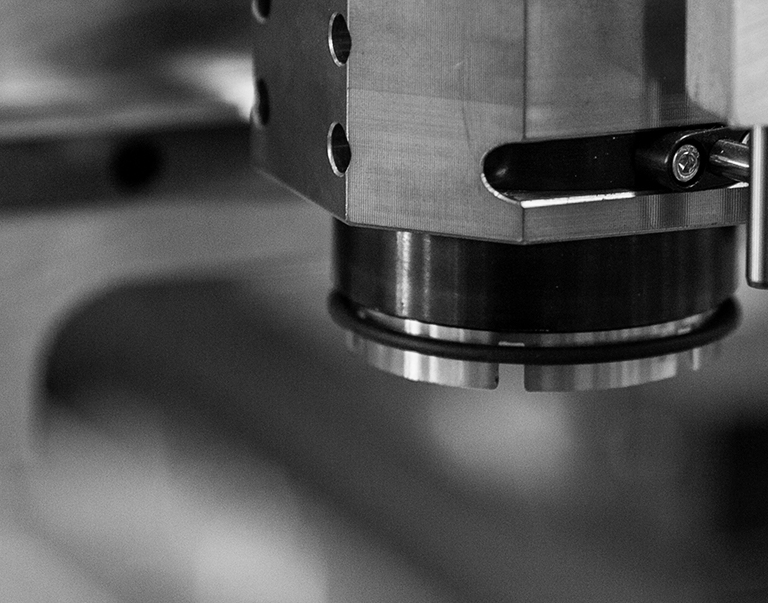

Our epoxy coating- and Hairpin systems are designed in a very compact way. The unusually high availability (> 95%) is achieved both by an imaginative handling technology and by reliable, proven transport equipment for the production goods in continuous operation in the epoxy coating plants. The following test features guarantee a very high quality:

- Thickness of the layer of the applied coating

- Edge cover

- Mechanical impact resistance of the coating

- Electronic insulation testing

Preventing the product from heating up before coating allows the excess powder to be recycled without waste. This is achieved by returning it to the “fresh powder”.

You need videos of our hairpin or epoxy coating machines? We would be pleased to send you information. Just click on the link.

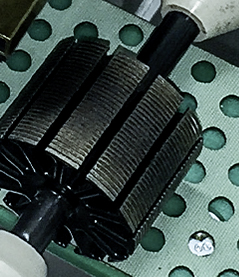

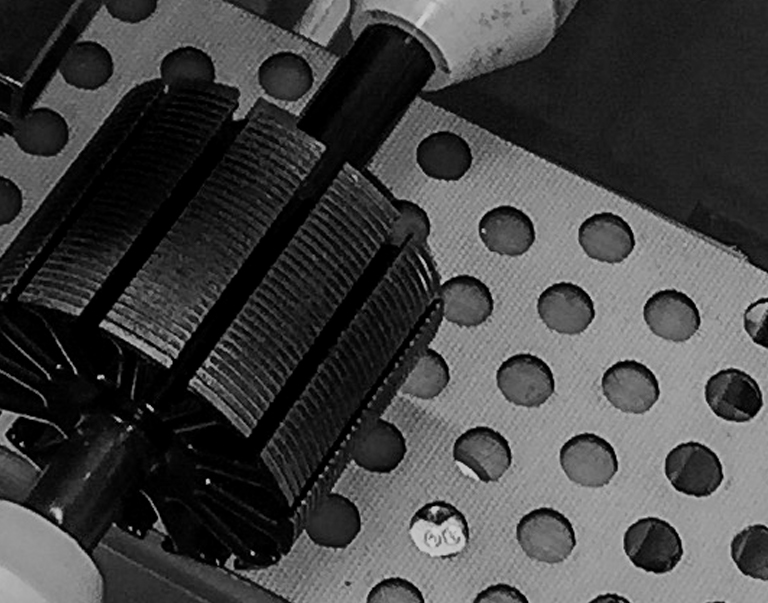

Hairpin

Powder Coating I-Pin and continuous Hairpin

An important process for e-mobility is stator powder coating. This welds the Hairpin pins

reliably with epoxy. Decades of experience with our epoxy coating systems have helped us to provide an optimized process.

On this white our customers can produce a safe and durable product with our Hairpin equipment.

Advantages:

Pens are reliably covered

low risk of bridging between the individual pins

Powder reaches even hard to reach places

Flexible assembly cells with scalable solutions

Here, too, the focus is on the ecologically sensible recycling of superfluous powder without waste.

Together with our partner we realize coating and impregnation solutions in the field of e-mobility. In this way, ecologically and economically meaningful synergy effects can be used.

You need videos of our hairpin or epoxy coating machines? We would be pleased to send you information. Just click on the link.