BS-Trayshuttle

THE AUTOMATED GUIDED VEHICLE SYSTEM (AGVS)

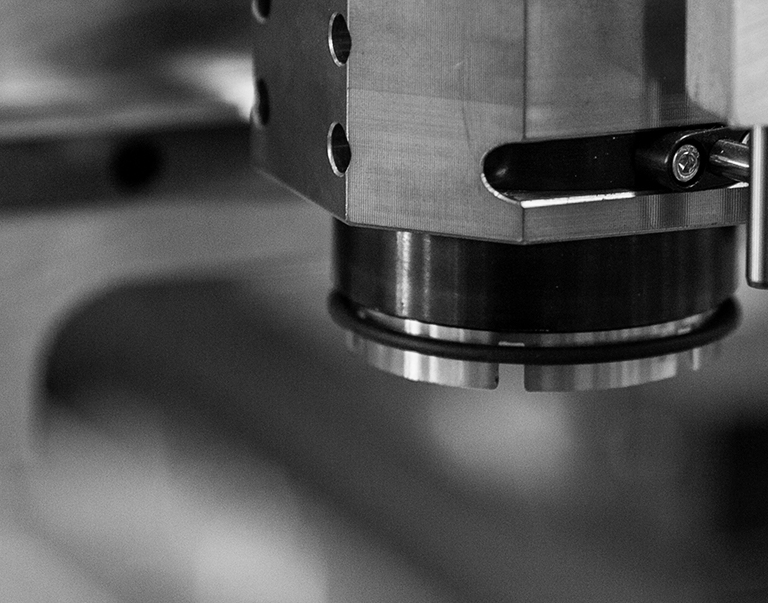

The productivity of production lines depends to a large extent on the efficiency of the internal transport logistics. With our automated guided vehicle system (AGVS), you profit from significant efficiency gains and cost reductions through the unmanned and direct delivery of materials to production lines. Our special machines make completely autonomous loading and unloading possible for you.

Almost everything is possible with AGVs, from tray loading to pallet loading. As a MiR partner (you can switch to www.mobile-industrial-robots.com by clicking on the link), we are available to answer any questions you may have about the design.

Das BS-Trayshuttle

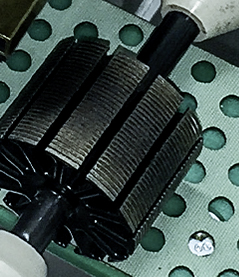

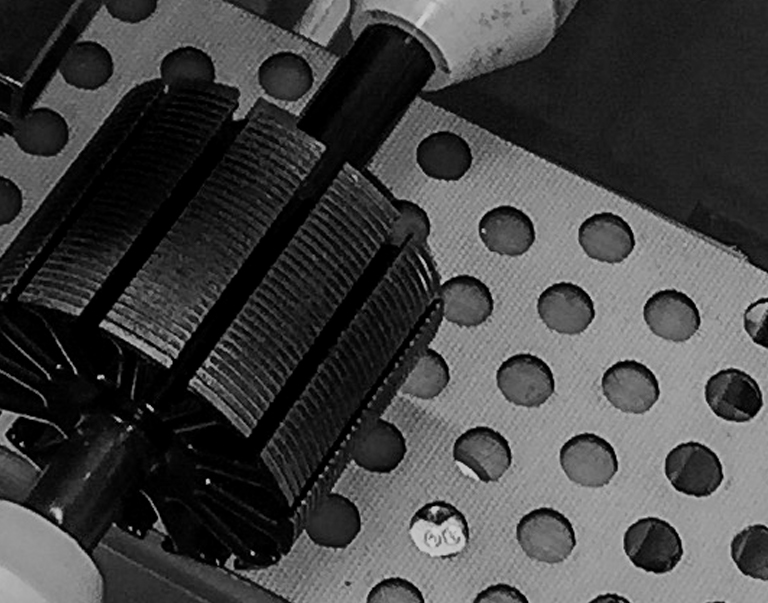

AGV – Automatic guided vehicle. The BS trayshuttle MiR250 is the link between logistics and manufacturing: With this Autonomous Mobile Robot (AMR) it is possible to autonomously map the supply and disposal of manufacturing equipment. For this purpose, e.g. the production material is picked up from the logistics areas and automatically fed to the production plant. Semi-finished products can also be transported to the next production stage. The integration of intermediate or buffer storage is also possible.

With the variable transfer height of 200 – 1200 mm, the BS trayshuttle MiR250 is the ideal complement to our BS palletizers. This creates

a complete system with high autonomy. See our Youtube video. (You change with link click on www.youtube.com).